A Brighter Packaging Future – Waste Reduction

We believe in mindful packaging use aimed at reducing energy, water use, and overall emissions.

Our plastic Blue Toad containers are 100% recyclable with zero added adhesives. A key part of our sustainability efforts is the fact that our containers are food safe. We encourage our customers to reuse them for a myriad of things: travel-sized toiletries, meal prep, even office or kitchen organization.

Not only does our unique square shape offer impressive space saving (it also looks great on the shelf) it also makes for more efficient and affordable distribution, resulting in savings to everybody involved!

Accelerated PLASTIC Degradation

As we think about sustainable packaging, it’s difficult to find a solution that ticks off all the boxes. There are a variety of packaging materials available for CPG businesses to retail their goods in, but what makes our Blue Toad packaging stand out?

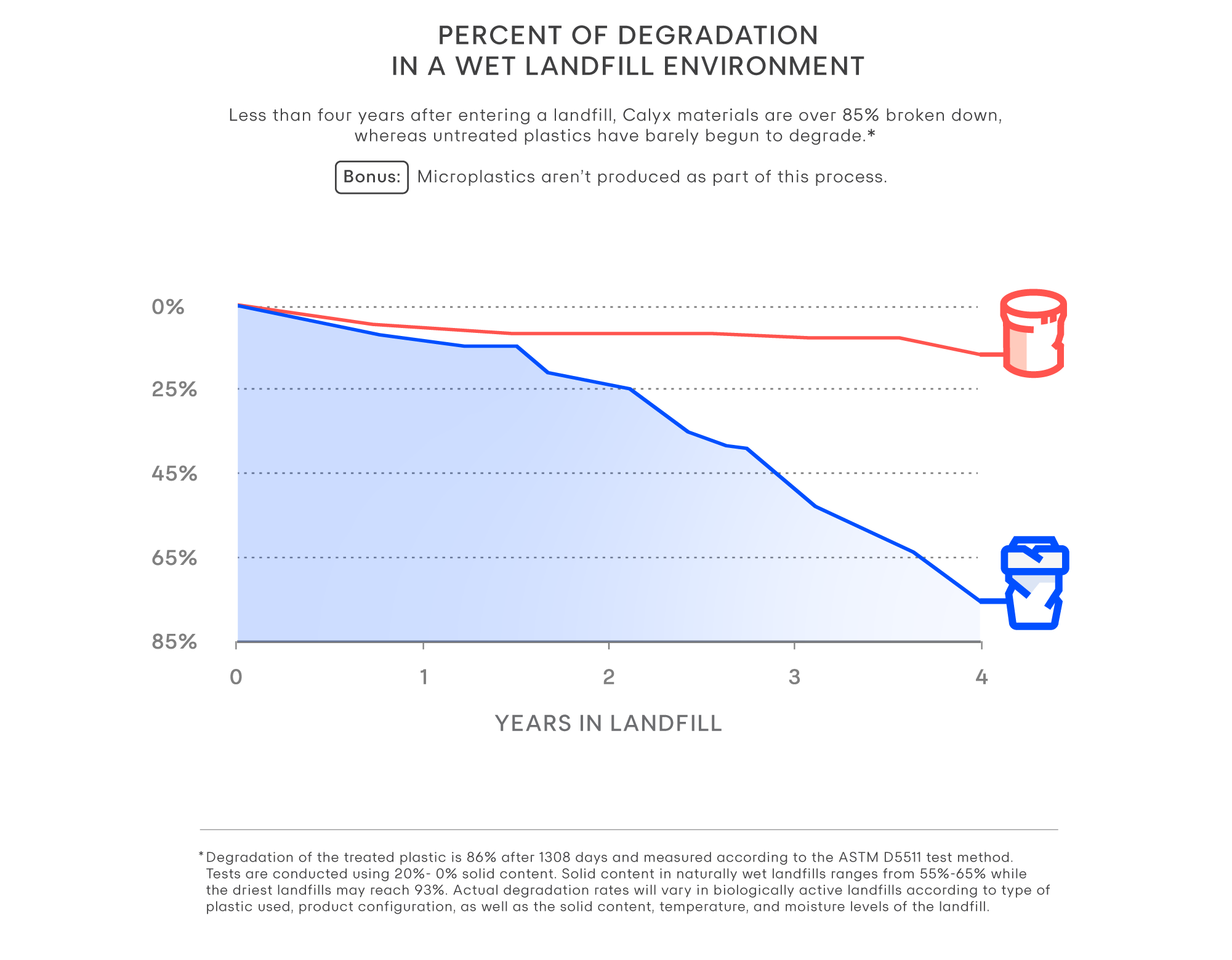

Enter Accelerated Degradation. Less than four years after entering an anaerobic landfill, Blue Toad containers are over 85% broken down. How do we achieve accelerated degradation? Our plastic containers (made by Calyx) have an organic additive that attracts microbes that eat the material—meaning it starts degrading as soon as it enters a biologically active landfill. This process does not produce microplastics like oxo- or photo-degradable plastics do.

Accelerated degradation is not to be confused with the term and buzzword, “biodegradable”. Biodegradable materials, under the right conditions and the presence of microorganisms, fungi, or bacteria, lead to packaging breaking down to its basic components and blending back in with the earth. In a perfect world, these substances would degrade without leaving any toxins behind. This however, is not always the case.

Blue Toad plastic containers leverage its organic additive to break down plastic to produce biomass, rather than microplastics. While this organic additive actively reduces our footprint in landfills and improves our products’ decomposition, there is potential to continue improving and innovating our materials in order to provide the best solution to the industry.

The image below is of me (Paul Frantellizzi) holding one of our original Non-GMO corn-based water bottles @ our local landfill. We have been focused on accelerated degradation and bio-plastics for over 15 years!!!

MADE IN THE USA

To reduce our emissions, we like to keep things local – really local. The transportation sector accounts for 27% of all of the greenhouse gas emissions produced by the US in 2020.

Blue Toad containers are manufactured in Salt Lake City, Utah. Therefore, our containers and lids are manufactured domestically in the United States, which means faster delivery with fewer emissions. Manufacturing here also means we follow very strict environmental regulations not always followed in other parts of the world.